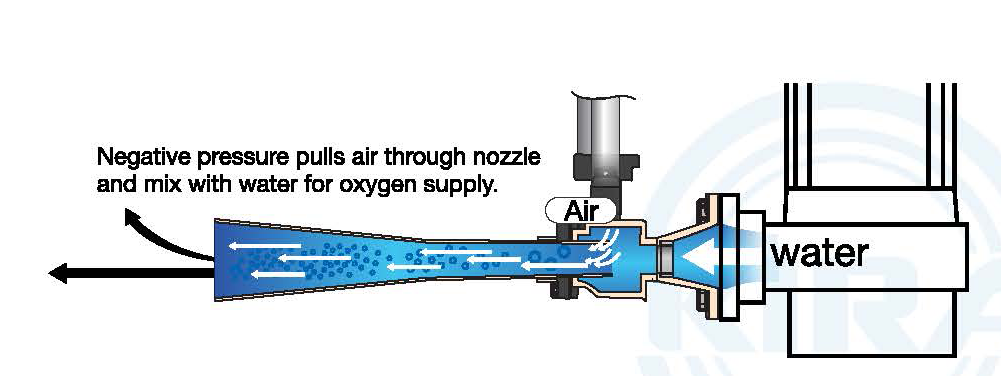

1. This special submersible pump is equipped with specific accessories to create jet power. When pump works, it generates high pressure pushing liquid through the narrow tube in special nozzle. This jet power creates strong current and negative pressure at the same time.

2. Special nozzle connects with air pipe up to surface of water. This negative pressure pulls air through pipe into nozzle which functions to be mixing chamber. This nozzle presses air into lots of small bubble and mix into liquid.

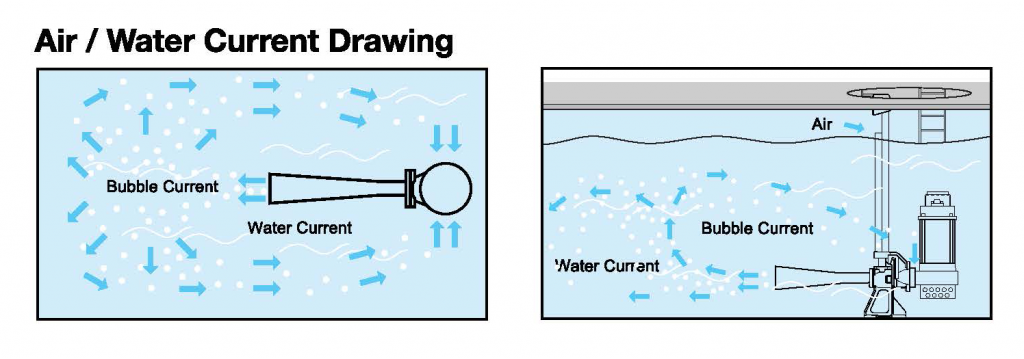

3. Liquid with small bubble is pressured through expansion pipe and, at last, flushed outside causing best circulation and creating oxygen supply.

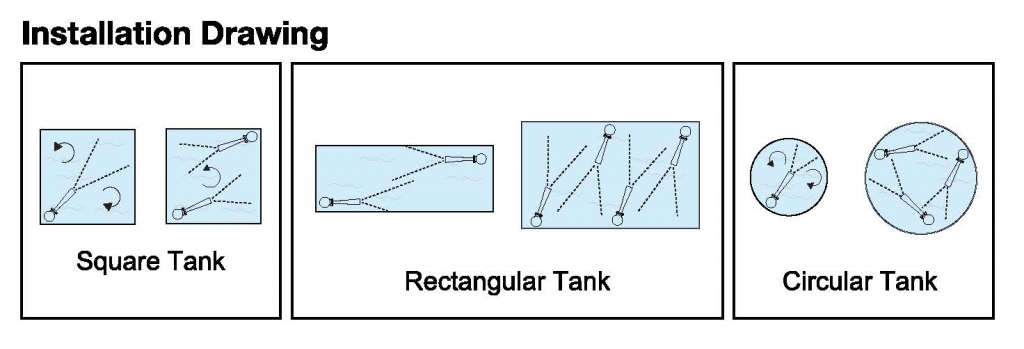

4. All submersible ejector can matched with the guide rail system for easy installation and maintenance.

Pre-aeration and mixing in wastewater treatment system Oxygen supply to a slurry treatment tank Air supply to aquaculture farm or fish pond

Special mix nozzle design provides high air flow with plenty of small air bubbles. This increases rate of oxygen supply. Special nozzle creates strong single airjet current direction and is enable vertical stirring movement. Low noise concept comes with submersible ejector type. Pump operates silently under water while it saves installation space. Easy installation and maintenance by using guide rail system makes system last long.

| Phase (VAC.) | 220 VAC. | 380 VAC. | 220 VAC. | 380 VAC. | 220 VAC. | 380 VAC. | 380 VAC. | 380 VAC. |

| Model | EP2.8-1S | EP2.8-1 | EP21.5-1.25S | EP21.5-1.25 | EP22.2-1.25S | EP22.2-1.25 | EP43.7-2 | EP45.5-2 |

| Motor Output | kW | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | |||

| Air-inlet Bore mm | (inch) | 25(1″) | 32(1.25″) | 32(1.25″) | 50(2″) | 50(2″) | |||

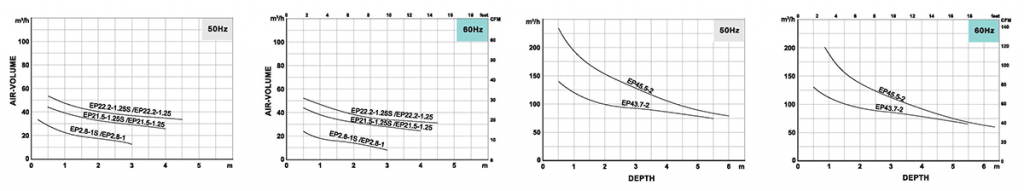

| Air Volume Depth | m3/h (m) | 15.5(2.5) | 26(3) | 38(3) | 90(3) | 130(3) | |||

| Max Water Depth | Max Water | 3 | 4 | 4.5 | 5.5 | 6 | |||

| Capacity | m3/h | 21 | 51 | 60 | 78 | 132 | |||

| Solid Passage | mm | 20 | 20 | 20 | 35 | 35 | |||

| Cable | m | 8 | 8 | 8 | 8 | 8 | |||

| Weight | kg | 19 | 18 | 34 | 30 | 37 | 32 | 71 | 112 |

| Tank Max Dimension(LxWxH) | m | 3x2x3 | 4×3.5×4 | 5x5x4.5 | 6x6x5 | 7x7x6 | |||

| Accessories | Ejector | BEP-1AP | BEP-11/4BP | BEP-11/4BP | BEP-2CP | BEP-2D | |||

| Accessories | Guide Rail | TEP-1AP | TEP-11/4BP | TEP-11/4BP | TEP-2CP | TEP-2D |

| Motor | Body | ||

| Frequency | 50/ 60Hz | Impeller | Semi open (Channel) |

| FC200 | |||

| Phase | Three-phase (Single-phase upon request) | M.seal | Double mechanical seal |

| CA/CE & SiC/SiC | |||

| Motor | Dry submersible induction motor | Bearing | Ball type |

| 2P (up to 2.2kW)/ 4P (3.7 – 5.5kW) | Upper Cover | FC200 | |

| Motor Frame | Stainless steel | ||

| Insulation | Class B (up to 2.2kW)/ Class F (3.7 – 5.5kW) | Shaft | Stainless steel |

| Protection | IP68 | Casing | FC200 |

| Protection Device | Auto-cut protector (built-in) | Diffuser | Stainless steel |

| Cable | VCT or H07RN-F or SJOW/SOW | ||

| Application Waste water, Sewage and Aeration in Farming | |||

| Liquid Temp 0 – 40 C (32 – 104 F) | |||

|

Type

|

Model | A | D | H | Q (lnch) | Remark | |

| 10 | 30 | ||||||

| Ejector | EP2.8-18 | EP2.6-1 | 712 | 179 | 450 | 1″ | Figure1 & Figure 2 |

| EP21.5-1.256 | EP21.5-1.25 | 881 | 207 | 520 | 1%” | Figure 3 & Figure 4 | |

| EP22.2-1.258 | EP22.2-1.25 | 881 | 207 | 520 | 1%” | Figure 3 & Figure 4 | |

| – | EP43.7-2 | 1113 | 314 | 638 | 2″ | Figure 3 & Figure 4 | |

| – | EP45.5-2 | 1380 | 374 | 788 | 2″ | Figure 3 & Figure 4 | |

| Gulde Pall | EP2.2-18 | EP2.8-1 | 742 | 179 | 485 | 1″ | Figure 5 & Figure 6 & Figure 7 |

| EP21.6-1.269 | EP21.5-1.25 | 900 | 207 | 590 | 1%” | Figure 8 & Figure 9 & Figure 10 | |

| EP22.2-1.256 | EP22.2-1.25 | 800 | 207 | 598 | 1%” | Figure 8 & Figure 9 & Figure 10 | |

| – | EP43.7-2 | 1133 | 314 | 832 | 2″ | Figure 8 & Figure 9 & Figure 10 | |

| – | EP45.5-2 | 1402 | 374 | 819 | 2″ | Figure 8 & Figure 9 & Figure 10 | |